Immediate gratification. That’s what we’re all looking for these days, with our Polaroid cameras, 3D printers and 60-minute grocery delivery services. There is an undeniable need for speed in our fast-paced lives, and this extends into the building sphere.

Brick-and-mortar buildings may still be de rigeur, but rapid construction techniques certainly no longer apply to only emergency or low-cost housing. These days, high-quality pod homes feature on the pages of glossy magazines, often with a Hollywood star in situ.

Cutting-edge architectural design and a space-age approach to utilitarianism contribute to the minimalist aesthetics, while large areas of glass in these so-called ‘pod homes’ allow your living space to blend into its immediate natural environment. In many ways, your interior mirrors the quality and aesthetics of your exterior, and vice versa.

These contemporary pods are often created to be fully off-the-grid, with solar energy and grey water systems incorporated into the house design, thus making them largely self-sustaining. Innovation around the building process focuses on off-site manufacturing methods, allowing companies to prefabricate single- or multi-storey structures into modular sections.

This enables a carbon-neutral approach, with advantages to both buyer and environment, as pod homes can be designed to fit into an existing structure or work as standalone units. Plug-and-play is the name of the game and – once these modules are transported to a site – you can immediately and easily start building on a pre-laid foundation.

Transport, wastage, manpower, fuel and other secondary costs are therefore hugely reduced during the process, and the main benefit to the end consumer is that they’re able to move into their new home within six to eight weeks. How’s that for immediate gratification?

Locally based modular home companies leading the charge in South Africa include brands such as HouseZero and Inizio, with both entities aiming to convert premium clients in search of a quality home to thinking ‘pod’. In addition to the immediacy factor, the other key selling points are sustainable living and environmentally friendly design.

Johannesburg-based HouseZero pioneered a completely new category in modular building. It was not aiming to create just another modular building system, and instead engineered a complete carbon-neutral solution, integrating contemporary aesthetics, green technology, interior design, smart house connectivity, solar energy, waste recycling and security.

Its Swiss-designed modular construction aims to tick all the relevant style boxes, striving for flow between airy open-plan spaces. It achieves this by using wood and glass surfaces, with premium finishes in both the bathrooms and kitchens.

At the heart of the HouseZero system you will find custom-engineered steel structures and high-tech flooring, with the wall and roof panelling manufactured off-site. The company strives for net-zero energy consumption, with climate control, energy management, lighting, shading and off-grid power integrated into the original structure.

Grid-independent modular homes feature roof panels incorporating solar power, thus ensuring they fully support the global trend towards net-zero carbon emissions goals. These modular homes will therefore generate and store their own power, with no need for connection to any power grid (all while avoiding the environmental burden associated with this).

There are still more ways in which modular houses can be made even more green. It would mean, however, that manufacturers would have to return to the proverbial drawing board. Just imagine, for a moment, that you could grow your substrate, rather than use destructive methods to mine it from the earth?

Hemp

This might be a good time for a slight redirection as we venture down a rabbit hole relating to the hemp industry in South Africa. Hempcrete lies at the centre of this potential industrial revolution – on a local as well as global scale – with the additional benefit of both kickstarting rural community development while helping to heal our damaged planet.

This hemp byproduct – basically manufactured from the fibrous hurd (or stalks) left after the actual hemp fabric and oils have been extracted – is set to become one of the touchstones on which future carbon-neutral building projects will be based. Previously, hurd would have been dumped, but hemp advocates are notoriously good at completing circular economy puzzles.

“We are committed to harmony of purpose and form and believe that spaces achieve their full meaning when the natural elements of light, wind and water are in balance with the affairs of human life,” explains Wolf (a mono-moniker), one of South Africa’s most innovative spatial minds.

This visionary space-meister is founder and principal eco-architect at the award-winning firm Wolf & Wolf Architects. Many industry peers view him as a leader in the sustainable building design field in SA, and it is therefore no wonder that he was one of the first building designers to use hempcrete in commercial and private projects.

South Africa is blessed with a suitably sunny climate, large areas of unused land and a massive rural population in search of employment opportunities. Hemp constitutes the missing piece in the circular economy puzzle; it grows quickly, requires little water beyond regular rainfall and – as a botanical species – it is inherently pest-resistant.

This means its cultivation can easily be outsourced to small-scale farmers, and that crops can be harvested without adding any toxins to the natural environment. In fact, well-planned plantations may even contribute to the phyto-purification of previously contaminated soils.

Additionally, a hemp harvest constitutes organic, durable and comfortable textiles, outshining cotton and competing crops by far when it comes to being planet friendly. Highly nutritional oils (and yes, they are completely non-psychoactive), are widely used in the cosmetics and food industry, and may even be processed to create an alternative to plastic.

It certainly ticks all the right boxes, but the deal-maker here is the fact that the cultivation of industrial hemp has the potential to substantially grow South Africa’s local economy, all while providing sustainable and dignified jobs. And did we mention this will be achieved without unnecessarily impacting the planet? This sounds too good to be true, right?

Wrong. At its most base form, making hempcrete is as simple as preparing the natural organic material used in building a cob house. Sub-soil, water and natural fibres are mixed together; with the former, the hurd is used instead of straw, while building lime replaces the mud. Et voila, you have a mix that you can shape into a wall!

The next step is to manufacture building blocks, similar in size and shape to a concrete brick. The ingredients remain the same, but the advantages of the hemp blocks will blow your mind: they are much lighter than concrete, deliver exceptional thermal insulation, and are simultaneously breathable and inherently airtight.

In effect, the hemp makes your walls vapour-permeable, thus regulating the internal relative humidity to eliminate condensation on interior surfaces. Superior characteristics – from both an ecological and economic perspective – yield regenerative positive energy gain to boot when compared with conventional building technologies.

I could go on about the material being 100% organic and therefore fully biodegradable. Or the fact that it has the potential to be a zero-waste material, because hempcrete can be re-used ad infinitum. Not to mention the unmatched sound insulation properties it delivers ...

The high liquid absorption rate of hemp also makes it both mould- and rot-resistant, plus it is resilient against microbes and insects. Best of all, as a crop it is sustainable to grow, harvest and process, making it a carbon-negative material that sequesters carbon dioxide from the atmosphere. (Yup, a hefty 108kg of CO2 can be locked away as biomass per cubic metre of the hempcrete for the lifespan of a building.)

In the end, this is a simple, low-tech construction method that creates a brand-new industry and job pool, and that is particularly relevant to SA’s economy. Sustainable building methods and materials do not only excite architects or rapid construction contractors, though.

Biophiles

Camilla Budden is one of a new breed of biophilic designers, and she believes that our living environment should be structured and understood "as a holistic, complex system".

“When you create a building, the interior and exterior must be integral to the landscape and environment it forms a part of,” explains Budden.

“I love plants and consistently learn new life experiences whenever I immerse my hands in the soil, and one key lesson is that your garden should complement your home, and vice versa.” Shade, wind protection, aural sound design, water conservation and aesthetics are a few of the factors contributing to the ‘outdoor feng shui’ on which biophilic design principles are built.

It is therefore no wonder consultants such as Budden now regularly work with city planners and urban designers to ensure buildings become an integral part of a thriving ecosystem. This, in effect, brings us full circle to the reason many buyers are opting for sustainable modular homes. This market segment is booming, with out-of-the-box thinking adding to the design elements on offer from leading players entering the pod home construction game.

South Africa-based reNRG is one firm pushing new innovations in the building sphere. It aims to do much more than just create modular homes from hemp. “Our key focus is to build – if you’ll excuse the pun – on and further develop existing technology, specifically our mobile app," explains CEO Machiel Marais.

“Security systems, as well as water and energy usage, will be controlled remotely through an integrated software programme,” he continues. “In addition, we plan to add structural design elements to the exterior frame, for example, shaping the roof to serve as a receptacle to catch rainwater, which will then be stored in a tank integrated into the building structure."

Greywater systems and overflow irrigation will assist in conserving water use; termite-mound funnelling will organically extract hot air; while roll-out hemp awnings and planting strategic trees will contribute biophilic elements to assist in temperature control and wind protection.

Wall planters and swivelling window boxes will allow you to have edible crops inside or outside the house, depending on weather. There will even be owl boxes, chicken coop attachments or ‘mini pet pods’ that can be slotted into your tiny house design to enhance its environmentally focused design.

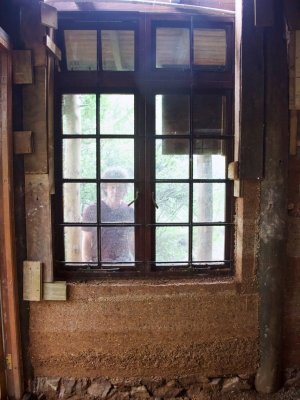

Albertus Louw, a television presenter for 50/50 on SABC 2, is currently getting his hands dirty while building his own hemp treehouse, and will be incorporating all the above principles as part of this experiential research and design experiment.

“In the end, our dedication should be to work towards finding an ultimate equilibrium, where the aesthetics of our living space combines with a regenerative environmental approach, both in practice and design,” says Louw.

His story will hopefully soon be part of a documentary series.

What a well-balanced world it would be if we all worked towards a mindset where regenerative principles were first and foremost when we planned our future homes.

The benefits of a modular home

There are many reasons why a modular home trumps a brick-and-mortar structure, but these points may be all it takes to change your mind.

- You save money.

Fast erection times, improved quality control and major savings on labour and transporting heavy raw materials means modular homes tend to be more affordable than their traditional counterparts. Obviously, size, design, finishes and location will affect the price. - You save time.

Most modular homes can be erected in six to eight weeks, which correlates to a massive saving in the actual costs linked to construction. Your building team will be a fraction of the size and will be on site for approximately a third of the time, which means a huge reduction in wastage, fees, infrastructure and pilfering. - You help save the planet.

Conventional construction is detrimental to the environment, while modular techniques are usually future-proof, using sustainable techniques and materials. Minimising transport, waste and water usage reduce the overall energy consumption during the building process. - You save future costs.

Modular panels are manufactured to be soundproof, water- and sun resistant and thermally efficient, so in-home energy and water usage can be reduced by 50% or more compared to conventional plumbing and electricity systems. - You save years (of your own life).

The panels used in many modular homes are made from organic materials such as wood or hemp, and these substrates are generally low in toxins. Materials that absorb less moisture (and are mould- and rot-resistant) mean an improvement in air quality, while the biophilic nature of the design helps you reconnect with nature.