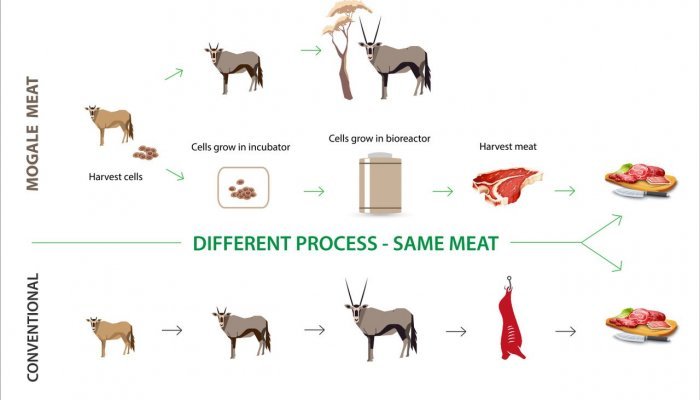

As the global demand for meat products grows, Paul Bartels, founder and CEO of Mogale Meat Company, says, “People want to eat meat, and it’s going to impact our food production.” Looking to the future, global food producers are seeing an opportunity to invest in the cultured meat space, which has grown exponentially since Acumen ran a story entitled Million Dollar Burger in 2020.

In just two years, the number of companies involved in the cultured meat value chain has grown from four to over 130. South Africa now also boasts two companies of its own: Mogale Meat Company and Mzansi Meat Co.

The global cultured meat industry

According to Crunchbase data, investors see enormous potential in this industry and have poured around US$2 billion into the space since 2020. Many companies are still in the research and development stage of their business cycles, but production is on the brink of starting. Those claiming to be at the point of delivering – American producers, for example – are still awaiting regulatory approval from the U.S. Food and Drug Administration and the U.S. Department of Agriculture. However, UPSIDE Foods in San Francisco, California, is confident that approval will come through this year, and it has already built a multi-billion-dollar plant.

In Singapore, GOOD Meat has started selling some of its products like chicken nuggets. The company also recently launched whole chicken fillets, but production numbers are small, and it can only sell small volumes weekly. Mosa Meat in the Netherlands has also started building its plant but is also awaiting regulatory approval from the European Union’s regulatory body. Future Meat and Aleph Farms in Israel are building their first plants, and Aleph Farms has already set up tasting kitchens and a glass viewing panel through which the public can set eyes on the bioreactors and the packaging equipment. Again though, this is on a small scale, says Bartels. Locally, Mogale Meat Company and Mzansi Meat Co. are also optimistic that they will have products to taste within months of the writing of this story.

As the industry prepares for production, many companies are now specialising and honing their focus on one aspect of the value chain. For example, some companies are developing the machinery needed to produce cell-based meats at volume, while others are working on improving the quality of the substrate (the liquid that feeds the cells) to enhance the speed, volumes and quality of the meat being produced. Companies and organisations are also looking at enhancing their skill sets and employing more scientists and people who can drive development and production. “If you look at all these cultured meat companies, they are all hiring staff,” says Bartels. “Mosa Meat has a 75-strong staff complement, and 50 of these people are scientists. So that tells you a lot of investment is going into this sector.”

Universities are also being encouraged to research and innovate. Bartell mentions UC Davis in California, Tufts University (which recently received a US$10 million grant from the United States government to start researching the space), Virginia Tech and Maastricht University in the Netherlands, which are all getting major funding to drive innovation in this field. But, Bartels says, “The majority of investment is coming from the private sector because they have seen the potential that this could become very big.”

Bottlenecks

However, Donovan Will, director of Pro-Veg South Africa, believes that while the idea of cultured meats is incredible, it is questionable whether it will be a common grocery item any time soon. “Memphis Meat [now UPSIDE Foods] has been saying ‘seven years’ for over 21 years,” he says, adding that there are still many hurdles and bottlenecks in the system.

Some challenges include long-term investment horizons, which Bartels says means investors will not see a return on investment any time soon. He also says that companies are not sharing their intellectual property, and as such, the development of products is slow.

One of the biggest challenges the industry is currently facing is that of scaling the product. Brett Thompson, co-founder and CEO of Mzansi Meat Co., raises this as a significant issue. He explains that most companies are still growing and producing products at the laboratory level, using laboratory-grade components and media or substrate. Moving from production in a laboratory to mass production is a major shift. In addition, he notes that in the R&D phase, most companies are working at a pharmaceutical level, meaning the production standards are much more stringent than at a food level.

The cost of production is also currently extremely high. But according to Will, this should be resolved when mass production starts. “The hardware costs will start coming down because people are focusing on creating food hardware instead of pharmaceutical hardware,” he says, explaining that pharmaceutical hardware is much more expensive than food-grade hardware. The cost of production is further exacerbated by the prohibitive cost of good quality growth serum. A quality substrate is essential to get cells to flourish and replicate. But as more companies enter the value chain and specialise in researching, designing, and working on one aspect of production, Will believes these costs will automatically come down, too.

Another reality of cell-based meat production is the space and machinery needed to produce massive volumes of meat. Will says, “If you produce beer in a 1,000-litre vat, you come out with 1,000 litres of beer, but in 1,000 litres of growth serum, you are getting about 100 litres of meat.” This means that large plants with large tanks are needed to produce in significant volume.

Healthy alternative

Global meat demand is growing, and the Australian Department of Agriculture says that global meat consumption increased by 58% between 1998 and 2018 and stands at around 360 million tonnes. Increased demand is not only due to global population growth (54%), but also the changing personal consumption of people as their preferences change and their wealth increases (4%). This means that developing and getting cell-based meats to market as quickly as possible will have a tangible, positive impact on the environment. It will address issues like forest and arable land degradation, as the cell-based meat production industry uses a lot less space and water while reducing the need for vast quantities of animal feed, fertilisers, and other resources needed to produce the world’s current meat supply. Also, because an animal is biopsied to get cells and not slaughtered, the number of animals bred and held in awful conditions will reduce dramatically. A single animal’s cells have the potential to produce tonnes of meat.

However, the benefits of cultured meat go beyond environmental and ethical concerns. As technology develops and producers increase their ranges, the possibilities around the types of meat products that can come to market are endless. In addition, producers have the ability to culture custom meat products to maximise health. So, while lean beef is good, the excess consumption of beef fat can result in health concerns. Producers can therefore create high-quality lean meat combined with healthier fats like venison or ostrich. This means that, ultimately, products retain their flavour without issues like fatty cholesterol, Bartels explains.

Furthermore, cultured meat will also be produced in clean and sterile environments, so the risk of contamination is extremely low, adds Thompson. He also stresses that cultured meats will not contain hormones and antibiotics because they are not raising animals to maximise output or in overcrowded conditions. This means that labs will not have to factor in the myriad of diseases associated with current agricultural practices, such as foot and mouth disease, mad cow disease, and avian influenza.

Putting cultured meat on the menu

However, the challenge of winning in this space is to market the product to meet the population's expectations. Thompson says it is essential to create products that people want or need – high-protein, low-fat burgers, for example. The key is to ensure that when the consumer picks up a real beef burger or a cultured meat burger, they cannot tell the difference. It must look, feel and taste the same, and the cost has to be comparable, says Thompson. Pro-Veg says that any strategy to launch alternative meat products successfully must include cost, taste and availability.

Will believes that everyday consumers are a good entry point for cell-based meats. “If you look at people lining up for McDonald’s and KFC, they have no idea what is in their food, and they don’t care, so if McDonald’s is serving lab-grown meat burgers, nobody is not going to eat them because of that.”

And when it comes to Africa, Mzansi Meat Co. and Mogale Meat Company are targeting their businesses to suit local markets. They are both aiming to produce African meats to service the local population as well as for export. Mzansi Meat Co., for instance, is looking at indigenous beef products and hopes to launch their burger soon, while Mogale Meat Company has plans to specialise in wildlife and indigenous beef and chicken. Bartels says they will have a chicken product in production by the end of the year.

With the end of 2022 around the corner, this looks to be the year where cell-based meat will take its first tentative steps to consumers' plates. It may not be the year that is remembered for the proliferation of this innovative technology, but it will be the year during which many consumers will be able to say, “I ate a lab-grown beef burger patty”.

KEY TAKEAWAYS:

- Food security is essential because the human population is set to reach 10 billion by 2050.

- Meat consumption is growing globally as population and per-capita incomes increase.

- Cultured meat is the most ethical and environmentally friendly way to provide meat on a massive scale.

- In the past two years, US$2 billion has been invested globally in the cultured meat industry.

- South Africa has two cultured meat producers on the verge of releasing their first products for tasting.